Zinc Electroplating Services in Chennai| 9444225539

Zinc Electroplating Service in Chennai –Specfin Industries is well-proven process for Zinc plating of ferrous metals. We are dedicated to quality.

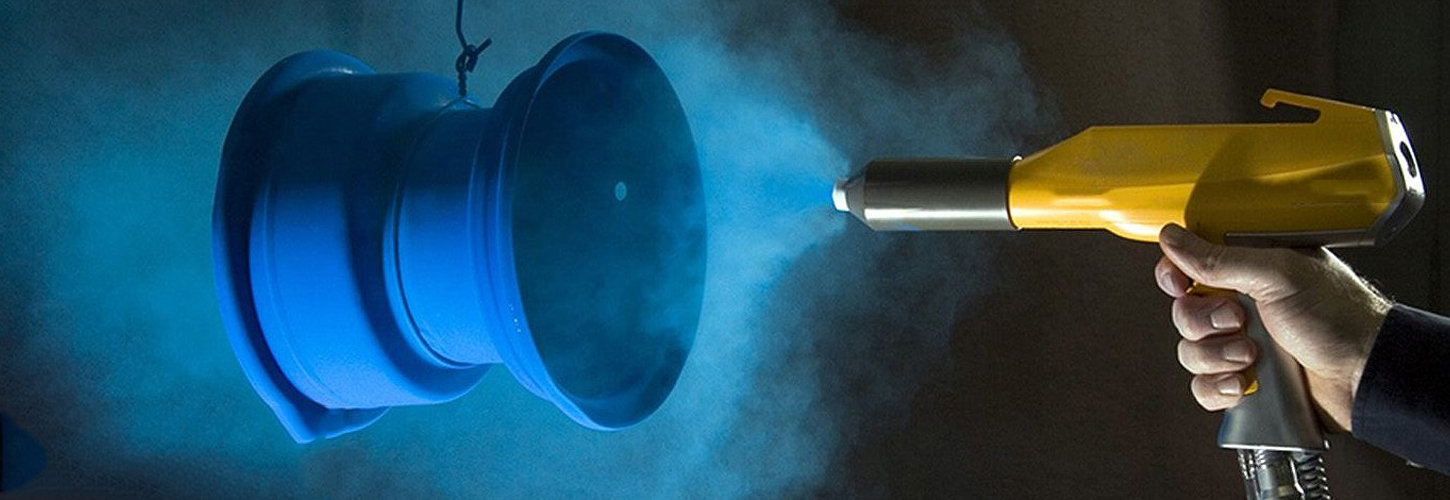

Zinc Electroplating Services In Chennai – Specfin Industries in Chennai has provided quality electroplating and metal finishing services for the automotive and general industry sectors for more than 25 years. Our plating company offers and specializes in compliant Zinc electroplating service with environmentally friendly trivalent passiveness and sealers.

Electroplating works by using electrical current to coat a conductive object with a thin layer of material, such as zinc plating, zinc-iron plating, or zinc-nickel plating in order to improve corrosion protection, add aesthetic qualities to the surface, allow for rubber to metal bonding, or increase abrasion and wear resistance.