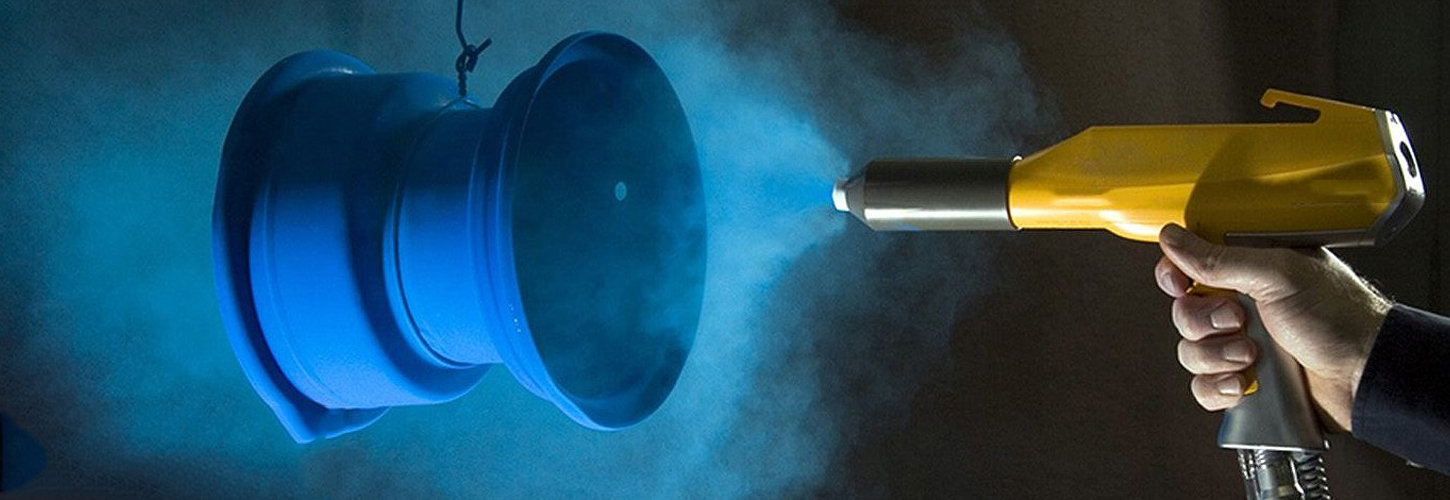

CED Coating Service in Chennai

CED Coating Service in Chennai – Specfin Industries is the provide a best quality CED Coating services in Chennai. We always focus on premium quality.

CED Coating Service in Chennai – Specfin Industries has passionately aimed to deliver quality service in surface treatment since its inception in 2010. Considered to be one of the best CED coating services, we have a fully Automated ED coating unit placed at Chennai, and have always ensured to cater the needs of our customer by constantly enhancing our capabilities to provide excellent and high standard assistance in treating the surfaces of the materials. We have a full equipped laboratory within our premises that facilitate us to check the quality and reliability of the coating. we are available a phone call: 94442 25539 and click away to meet your bulk orders.

specfin industries has specialized in Tin, Dull Nickel, Zinc Electroplating & CED Coating services and Ced Coating Services in Chennai, Electroplating Services, Powder Coating Services in Chennai, Spray Painting Services in Chennai to industry.