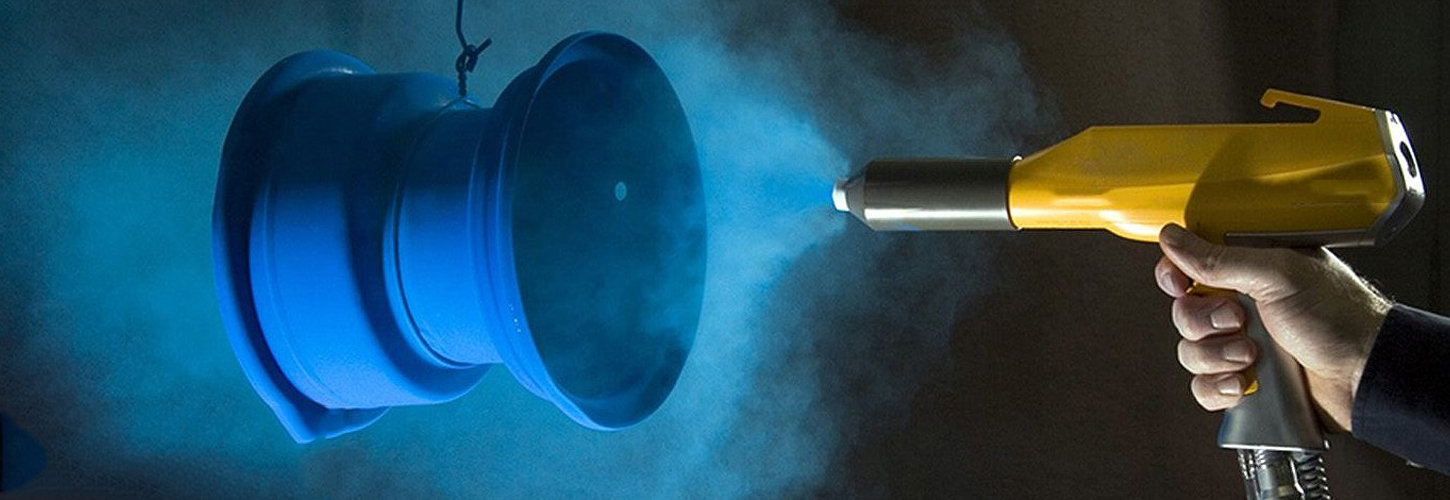

Tin plating increase the surface hardness of the material, provides uniform and dense coating, and in many cases ,maintains the same surface finish the material had before plating. Tin plating consists of the deposition of a tin alloy onto the metal surface by a chemical bath, not by electrodes or external charges. This permits the plating of hard to reach surface, such as small or deep bores and intricate shapes.

Tin plating can be used in the as-deposited condition or may be hardened, depending on the intended service condition.

- For corrosion Resistance

- For wear resistance in hard to reach areas

- Corrosion resistance and good resistance for adhesive wear

- Good solder ability

- Resistance welding is possible after deposition of tin

- Not very sensitive to finger prints

- Good contact properties

- Approved for used in food industry

High Standards Great Result

Tinning is the process of thinly coating sheets of wrought iron or steel with tin, and the resulting product is known as tinplate. The term is also widely used for the different process of coating a metal with solder before soldering.

It is most often used to prevent rust, but is also commonly applied to the ends of stranded wire used as electrical conductors to prevent oxidation (which increases electrical resistance), and to keep them from fraying or unraveling when used in various wire connectors like twist-ones, binding posts, or terminal blocks, where stray strands can cause a short circuit.

We Also Provide More Decorative Finishes For

- Furniture & display equipment manufacturers

- Plumbers Merchants

- Classic Car and Motor Cycle Restorers

All processes are rigorously controlled to ensure all coatings and finishes confirm with the relevant British Standards, Defence Standards, American Military Standards or customer specific process specifications.

Specfin Industries is a member of the Metal Finishing Association part of the Surface Engineering Association and we are also a sustaining member of the Institute of Material Finishing.